Mezzo Technology

Microtube Products

Lightweight. Compact. Aerodynamic. Proven.

Microtube Technology is:

Microtube durability and efficient heat transfer capabilities set it apart from other types of heat exchangers, making it ideal for a wide range of applications.

- Compact & Lightweight

- Reliable & Durable

- Resistant to Air-Side Fouling

- Aerodynamic

-

Optimal in High Pressure &

High Thermal Applications - Corrosion Resistant

Radiators

- Military ground vehicles

- Condensers and evaporators

- Directed energy heat exchangers (gas coolers)

- High Performance Automotive Racing (Formula 1, LMP 1, IndyCar)

- Environmental Control Systems for Aircraft

Radiators

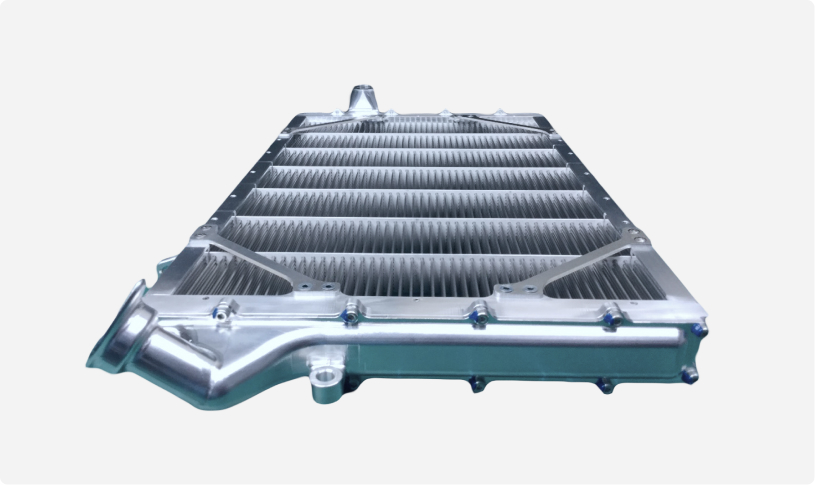

Our microtube radiators with crossflow offer significant advantages over competing options like plate-fin technology.

Exceptional heat transfer with low airside pressure drop. Compared to other radiators, provide up to a 30-40% reduction in airside pressure drop, saving customers on fan power.

- In-line tube patterns prevent airside fouling and make maintenance easier.

- Excellent resistance to foreign object damage.

- Polymer tubes offer significant weight savings compared to other technologies.

- Lightweight in high-temperature applications where aluminum is not a suitable material.

- High-performance in high-pressure applications (microtubes are pressure vessels).

- Military ground vehicles

- Condensers and evaporators

- Directed energy heat exchangers (gas coolers)

- High Performance Automotive Racing (Formula 1, LMP 1, IndyCar)

- Environmental Control Systems for Aircraft

Intercoolers

Our microtube coolant-air intercoolers are designed to be highly compact while delivering exceptional thermal performance with low charge air pressure drop.

To achieve the best possible performance, we recommend pairing our intercoolers with our high-performance radiators.

- Extremely low charge air temperatures (often within a few degrees of the inlet coolant temperature)

- Low charge air pressure drop, improving overall system efficiency

- Compact design, making them ideal for applications with limited space

- Durability and reliability, even in extreme environments

- Military Ground Vehicles

- Aircraft

- High Performance Automotive Racing (Formula 1, LMP 1, IndyCar)

Intercoolers

- Military Ground Vehicles

- Aircraft

- High Performance Automotive Racing (Formula 1, LMP 1, IndyCar)

High Pressure/High Temperature Heat Exchangers

- Modular Nuclear

- Supercritical CO2 Heat Exchangers

- Heat exchangers for combustion processes involved in propulsion for space vehicles.

High Pressure/High Temperature Heat Exchangers

Microtubes are ideal for high-pressure applications due to their ability to efficiently contain high-pressure fluids and maintain a high heat transfer to volume ratio, which lowers the size and cost of heat exchangers.

Superalloy microtubing, like Inconel 625 and Haynes 282, makes it possible to use microtubes in high-temperature scenarios. For example, Mezzo is developing a 5 MW supercritical CO2 recuperator designed to withstand temperatures up to 800°C and pressures up to 3750 psi using microtubes for optimal heat transfer efficiency.

- Modular Nuclear

- Supercritical CO2 Heat Exchangers

- Heat exchangers for combustion processes involved in propulsion for space vehicles.

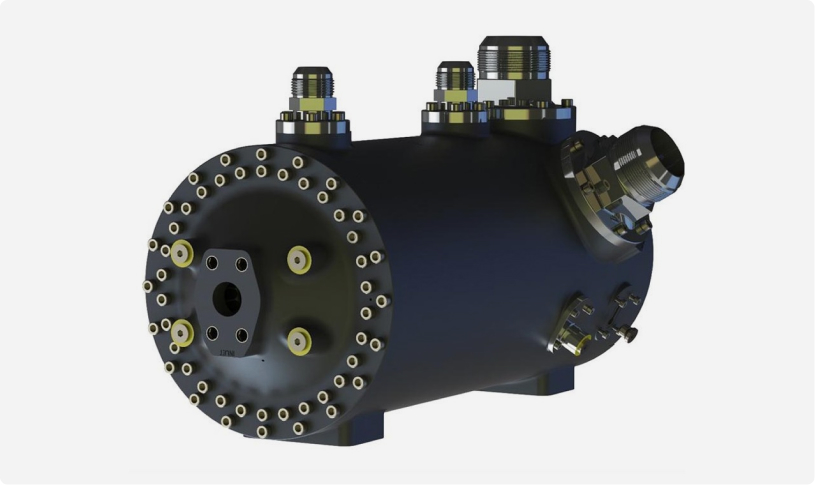

Oil Coolers

Our oil-liquid heat exchangers are compact, lightweight, and provide significant weight savings.

Typically, the oil pressure drop is reduced compared to conventional oil coolers.

- Mezzo oil-liquid heat exchangers come in cylindrical or rectangular shapes and can be designed as a cartridge to be inserted into a shell.

- Microtube oil-liquid heat exchangers are a type of liquid-liquid heat exchanger with similar attributes.

Mezzo’s microtube oil-air heat exchanger is highly resistant to airside fouling, making it ideal for harsh environments.

Microtube oil-air heat exchangers offer excellent thermal performance, comparable to Mezzo’s radiators, with a 30-40% reduction in air-side pressure drop for equal frontal areas, air flow rates, and specified heat transfer.

- The microtube oil-air heat exchanger, like Mezzo’s radiators, is also highly resistant to foreign object damage (FOD).

- Auto Racing

- Military Ground Vehicles

- Aircraft

- And More

Cryogenic Recuperators

- Unique applications where cryogenic heat loads are extremely high.

Cryogenic Recuperators

To function efficiently, the Reverse Brayton Cycle requires a high-performance recuperator with an effectiveness rate of around 99.8% and low-pressure drops that do not exceed 1% of the full-scale absolute pressure of each fluid.

- Mezzo, in partnership with its customers, has developed custom recuperators that are highly effective and cost efficient, making it an ideal choice for use in the Reverse Brayton Cycle.

- Unique applications where cryogenic heat loads are extremely high.

Bleed Air Coolers

Microtube bleed air coolers, made from high temperature alloys provide an unsurpassed combination of thermal performance and weight savings.

- Mezzo microtube bleed air coolers are widely adopted.

- Commercial & Defense Aerospace

Condensers & Evaporators

- Military Ground Vehicles

- Commercial & Defense Aircraft

Condensers & Evaporators

Microtube condensers and evaporators can be fabricated into various shapes and deliver a high-performance, compact solution when weight and volume are critical factors.

Thermal models that predict the performance of microtube products involving phase change (i.e. refrigerants) can be extremely complex. At Mezzo, we leverage our advanced thermal models and database of past empirical results to provide products that deliver superior performance and meet customer requirements.

- Military Ground Vehicles

- Commercial & Defense Aircraft

Phase Change Material HXs

The use of a sparse array of microtubes makes it possible to simultaneously extract energy efficiently from the entire matrix of phase change material while also consuming a very small fraction of the overall volume of the phase change heat exchanger core. This fact is the reason the microtube approach leads to weight savings.

- Applications with short duty cycles

Microtube Shell & Tube

- High Performance Automotive Racing (Formula 1, LMP 1, Daytona Protypes) Ground Vehicles

- Military

- Aircraft

- High Temperature/High Pressure Heat Exchange (Supercritical CO2, Modular Nuclear)

- Space

Microtube Shell & Tube

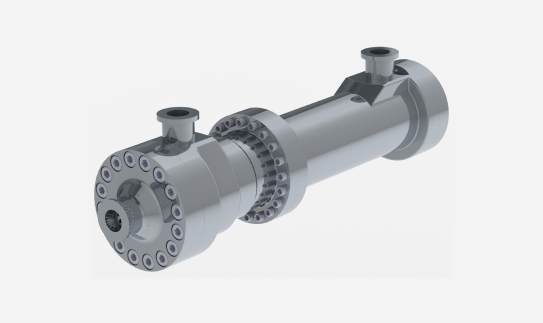

Mezzo’s cylindrical shell-and-tube microtube heat exchangers offer compact and high-performance solutions for various applications.

The shell and tube designs cater to the diverse needs of products such as intercoolers, oil coolers, recuperators for high-pressure CO2 power plants, condensers, and evaporators.

- Microtube shell-and-tube heat exchanger designs exist for intercoolers, a wide variety of liquid-liquid heat exchangers, condensers and evaporators, recuperators, etc.

- Mezzo’s shell and tube heat exchanger is used in a wide range of operating conditions, including aggressive high pressure and high temperature applications (3500 psi, 800 C).

- High Performance Automotive Racing (Formula 1, LMP 1, Daytona Protypes) Ground Vehicles

- Military

- Aircraft

- High Temperature/High Pressure Heat Exchange (Supercritical CO2, Modular Nuclear)

- Space

Our state-of-the-art engineering team, technical expertise, and real-world experience will take your performance to the next level.

Visit ACE Thermal Systems:

Developer and manufacturer of state-of-the-art bleed air heaters and vapor-cycle air conditioners for turbine helicopters and fixed-wing applications.